About Lithium-ion Battery

Lithium-ion custom battery packs applications include Consumer Electronics, Intelligent Household, Light Power Products (electric tools, toys, electronic cigarettes, model aircraft, unmanned aerial vehicles (uavs), medical equipment, AGV robot, auto stop power supply), Lighting(emergency lighting, industrial lighting, outdoor lamps and lanterns, miner’s lamp), Surveying and Mapping Instruments (total station, detector), RFID products (barcode scanners, handheld printers, POS machine) and other special equipment.

WHAT IS LI-ION BATTERY?

A Lithium ion battery or Li-ion battery (abbreviated as LIB) is a type of rechargeable battery in which lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. Li-ion batteries use an intercalated lithium compound as one electrode material, compared to the metallic lithium used in a non-rechargeable lithium battery.

THE DEVELOPMENT OF LI-ION BATTERY

- 1991 – Sony and Asahi Kasei released the first commercial lithium-ion battery.

- 1996 – John Goodenough, Akshaya Padhi and coworkers proposed lithium iron phosphate (LiFePO4) and other phospho-olivines (lithium metal phosphates with the same structure as mineral olivine) as positive electrode materials.

- 2001 – Zhonghua Lu and Jeff Dahn file a patent for the lithium nickel manganese cobalt oxide (NMC) class of positive electrode materials, which offers safety and energy density improvements over the widely used lithium cobalt oxide.

- 2002 – Yet-Ming Chiang and his group at MIT showed a substantial improvement in the performance of lithium batteries by boosting the material’s conductivity by doping it with aluminium, niobium and zirconium. The exact mechanism causing the increase became the subject of widespread debate.

- 2004 – Chiang again increased performance by utilizing lithium iron(II)phosphate particles of less than 100 nanometers in diameter. This decreased particle density almost one hundredfold, increased the positive electrode’s surface area and improved capacity and performance. Commercialization led to a rapid growth in the market for higher capacity LIBs, as well as a patent infringement battle between Chiang and John Goodenough.

- 2011 – lithium-ion batteries accounted for 66% of all portable secondary (i.e., rechargeable) battery sales in Japan.

- 2012 – John Goodenough, Rachid Yazami and Akira Yoshino received the 2012 IEEE Medal for Environmental and Safety Technologies for developing the lithium ion battery.

- 2014 – commercial batteries from Amprius Corp. reached 650 Wh/L (a 20% increase), using a silicon anode and were delivered to customers.The National Academy of Engineering recognized John Goodenough, Yoshio Nishi, Rachid Yazami and Akira Yoshino for their pioneering efforts in the field.

- As of 2016, global lithium-ion battery production capacity was 28 gigawatt-hours, with 16.4 GWh in China

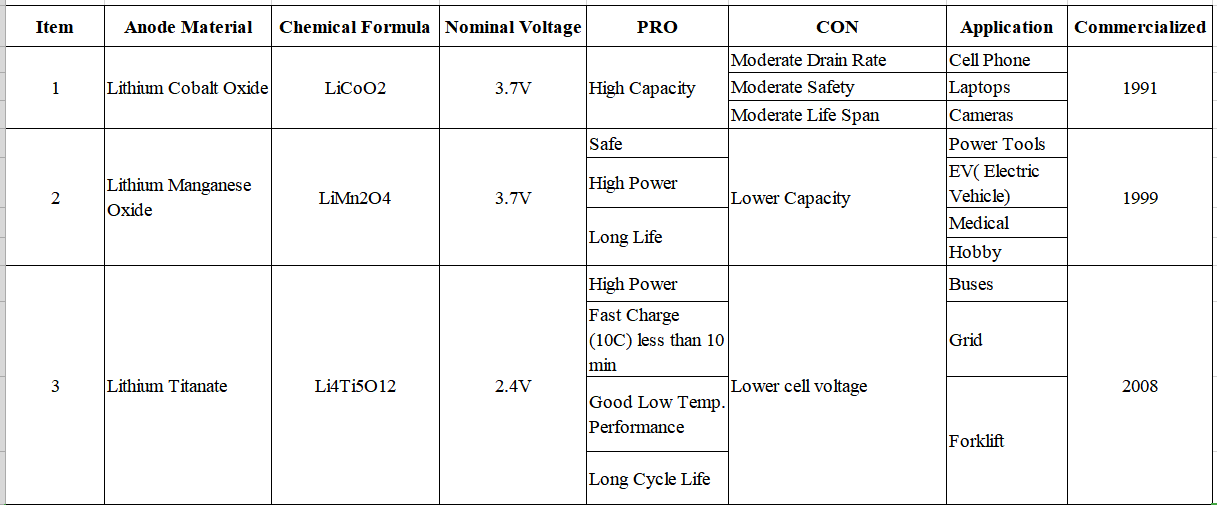

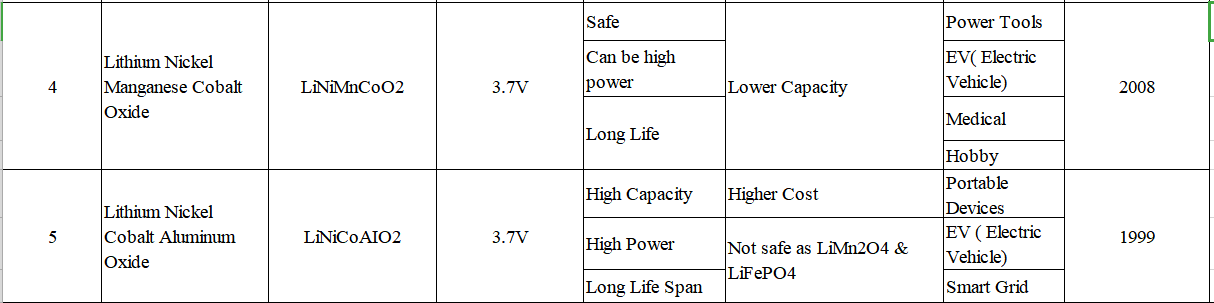

LI-ION BATTERY CLASSIFICATION

Classification by Cathode Material / Pro /Con /Application:

LI-ION BATTERY CLASSIFICATION BY SHAPE

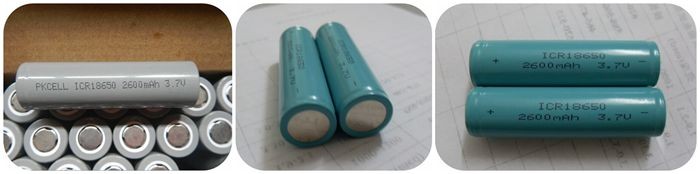

Lithium-ion cells are made in various sizes, often assembled into packs for portable equipment. Mainly cylindrical ( steel shell )and prismatic (aluminium shell) .

Many types are also available with an internal protection circuit to prevent over-discharge and short-circuit damage. This can increase their physical length; for example, an 18650 is around 65 mm (2.56 in) long, but may be around 68 mm (2.68 in) long with an internal protection circuit. Safe and economic recharging requires a charger specified for these cells.

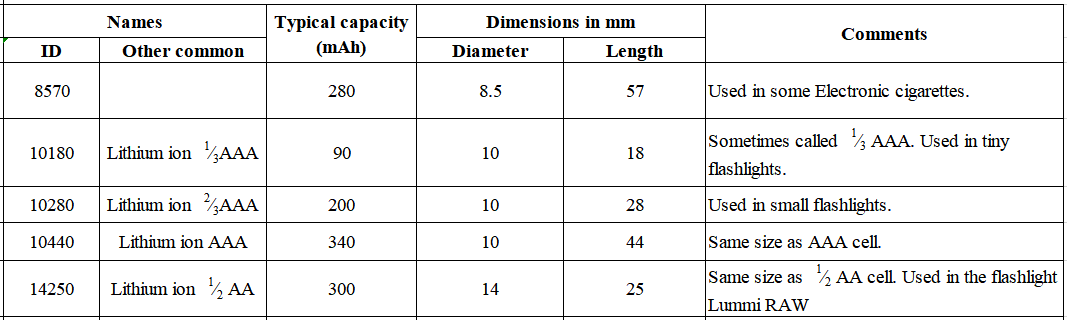

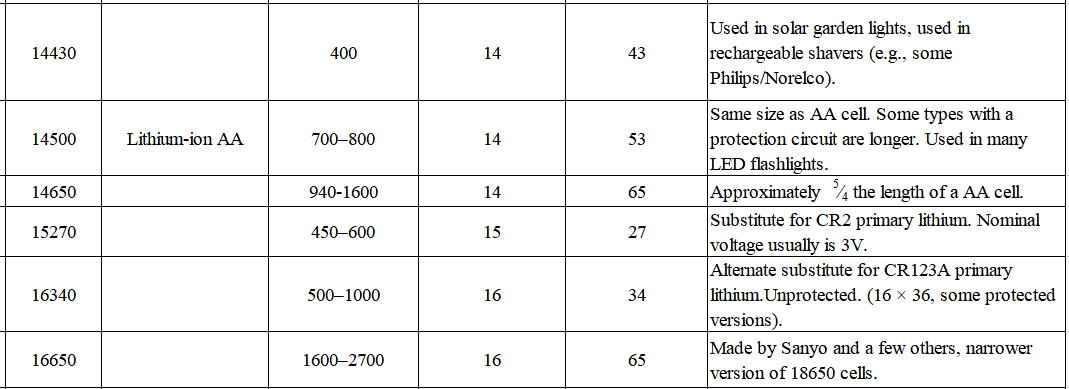

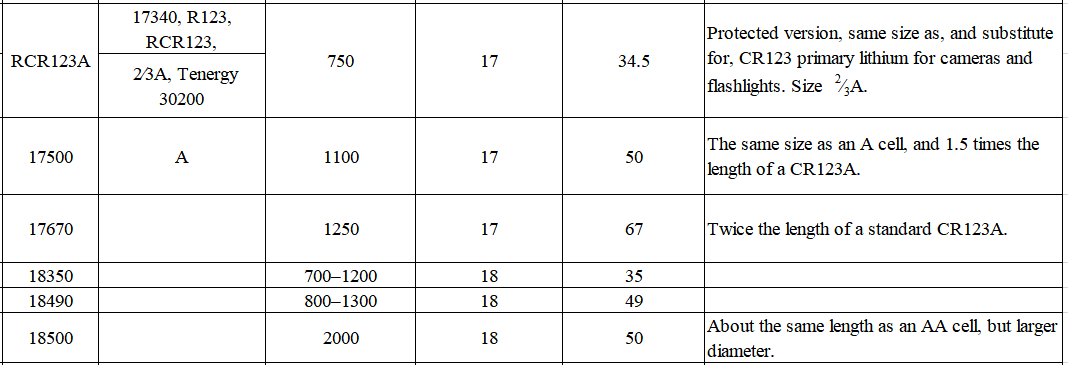

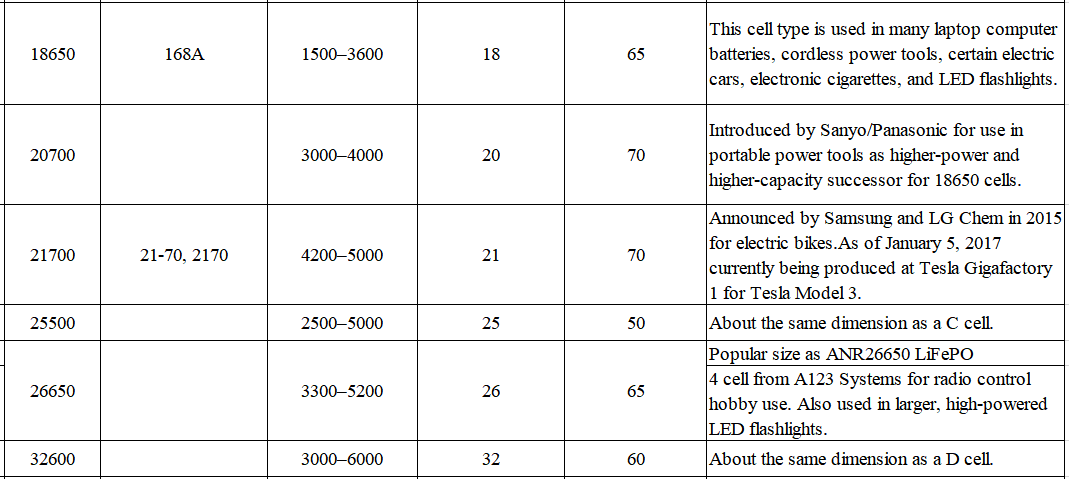

Commonly-used designation numbers indicate the physical dimensions of the cylindrical cell, in a way similar to the system used for lithium button primary cells. The larger rechargeable cells are typically assigned five-digit numbers, where the first two digits are the (approximate) diameter in millimeters, followed by the last three digits indicating the (approximate) height in tenths of millimeters.

This form shows almost all the cylindrical Li-ion cell. They can meet customers’ different dimension / capacity requirements.

For prismatic aluminum cell, there are so many types. Here we’ll show you the main .

LI-ION BATTERY APPLICATIONS

Popular applications include Consumer Electronics, Intelligent Household, Light Power Products (electric tools, toys, electronic cigarettes, model aircraft, unmanned aerial vehicles (uavs), medical equipment, AGV robot, auto stop power supply), Lighting(emergency lighting, industrial lighting, outdoor lamps and lanterns, miner’s lamp), Surveying and Mapping Instruments (total station, detector), RFID products (barcode scanners, handheld printers, POS machine) and other special equipment.

Just let us know your requirements, Lithiumbatterychina engineer will evaluate and provide you best solution.

- Your RFQ will be reply within 24 hours normally. Sometimes have a little delay due to the weekends or holidays.

- We work time from Monday to Friday (8:00-17:30 GTM+8)

- If you don’t receive Lithiumbatterychina feedback after 48 hours, please check your E-mail spam

- Contact US and we will be on service of you until you are satisfied with your purchase.

Our Factory

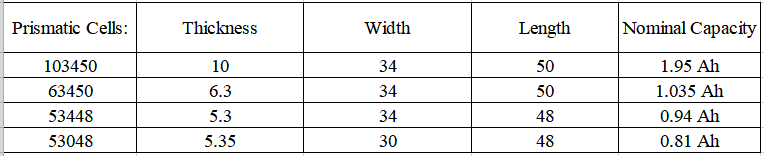

Production Process

Certificates